[compact] 2.0

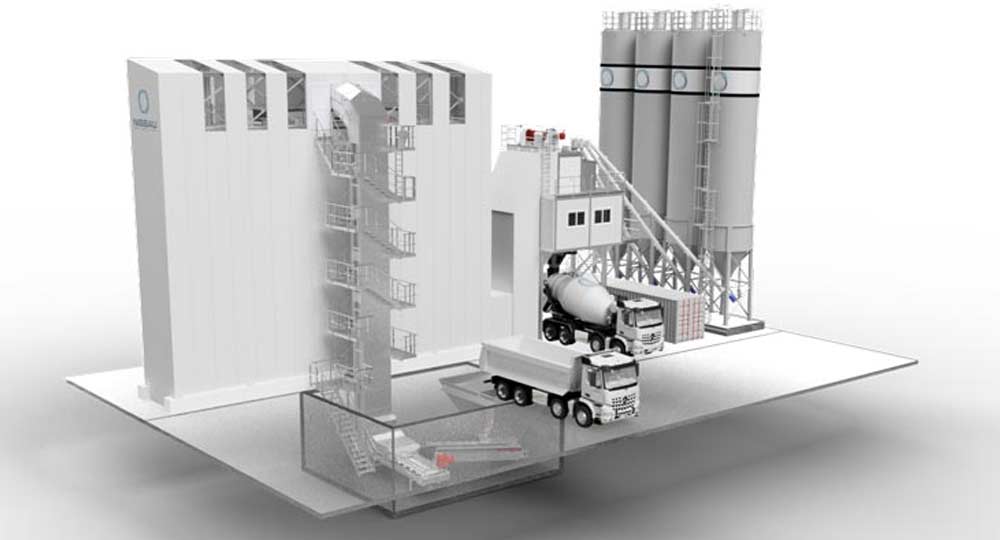

compact modular concrete batching plants, mixing STATIONS in combination with economical high storage and loading systems.

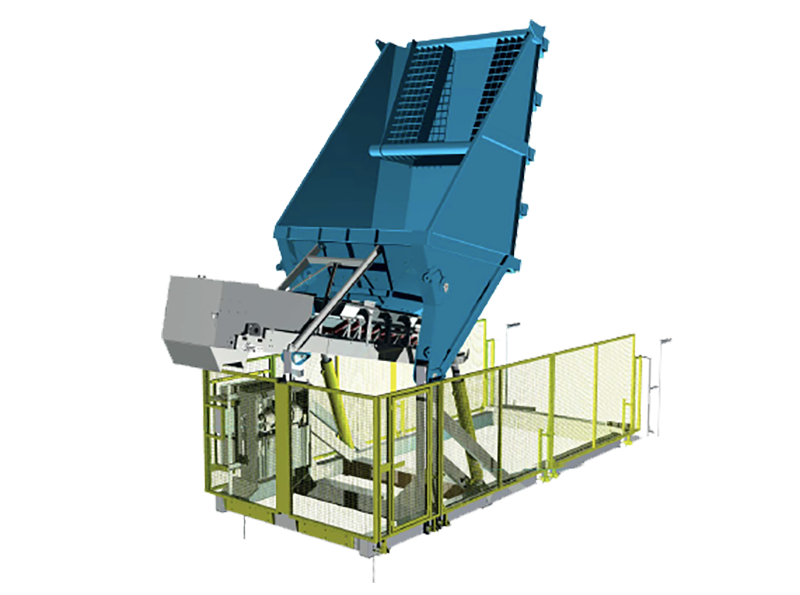

COMPACT MIXING STATION with skip bucket system.

double winch – weighing device – half reservoir FOR CONTINUOUS OPERATION OF THE DUMP BUCKET.

Perfectly matched to market and customer needs, our system technology impresses with a wide range of customization options and high-quality workmanship. We only use components from renowned manufacturers and use them in a way that does not allow our systems to work at their performance limits, but that they always have enough reserves, which makes your system safe and available even at peak loads.

Mixer sizes 2 -3.3 m³

max 2m³

modular construction with semi and full cladding

Winter and heating operation OF THE SYSTEM

Assembly time

2 DAYS

Skip bucket double winch

90.00 degrees

We rely on high-quality components from well-known manufacturers

our [massstab] in the field of skip bucket systems.

OUR COMPACT CONCRETE MIXING STATIONS ARE INDIVIDUALLY CONFIGURABLE.

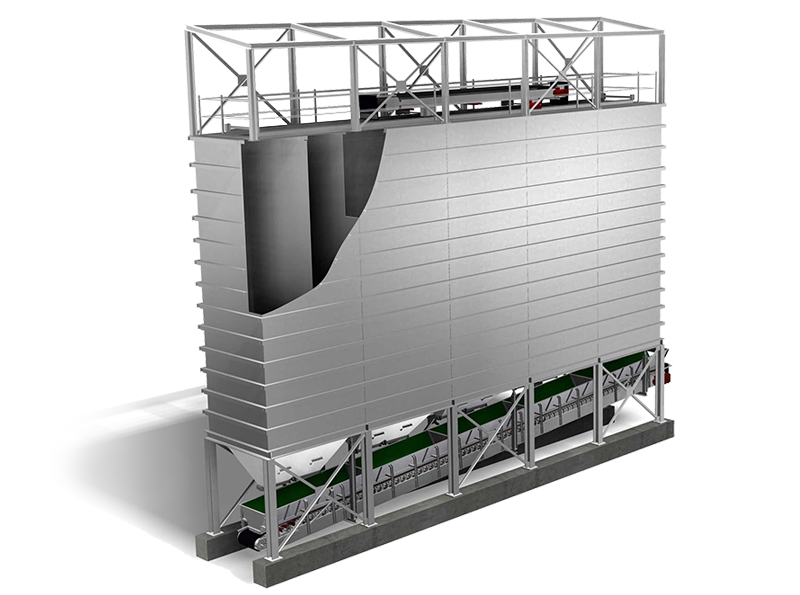

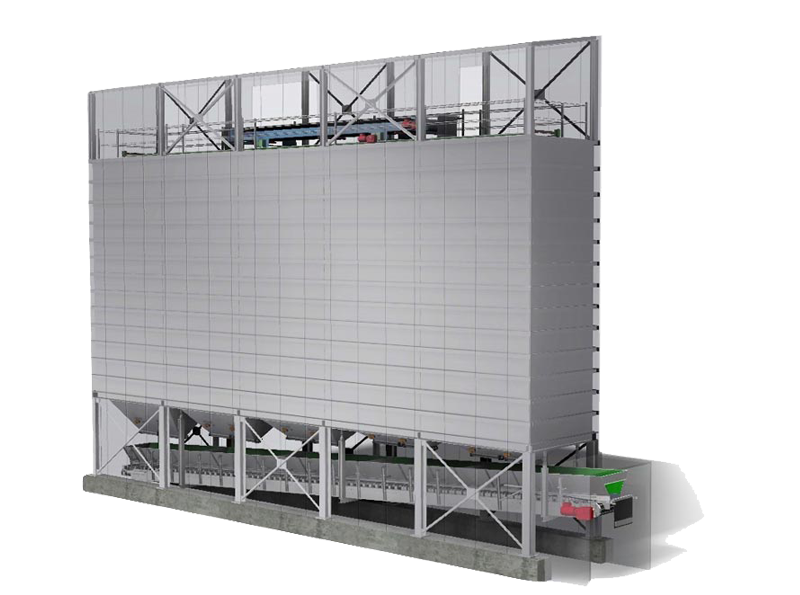

Multi-chamber silos

Sizes from 4-5 chambers and capacity from 132 cbm to 450 cbm.

High silo systems in a modular design

High silo systems in modular design. Factory cabling of the modules with connectors and integrated insulation. Sizes from 4-5 chambers and a capacity of 132 cbm to 450 cbm.

Feeding systems for every challenge

Our portfolio includes the following systems:

- Feeding systems below zero level

- Feeding systems above zero level

- Double conveyor belt

- Skip bucket elevators

- Overhead conveyor belt

- Inclined belts

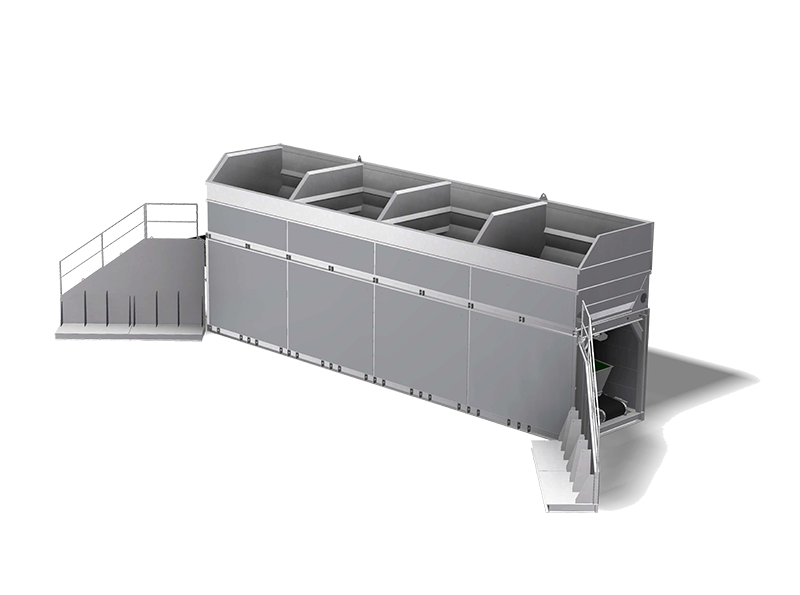

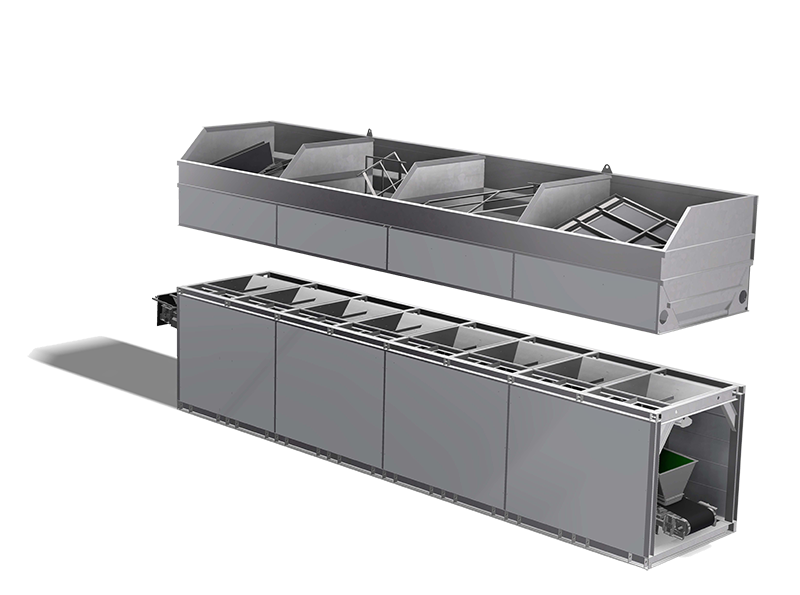

Modular aggregate store in a horizontal design

Modular aggregate storage in horizontal design, with integrated ramp and skid construction. Chambers: 3 – 6, capacity: 25 – 30 cbm per chamber

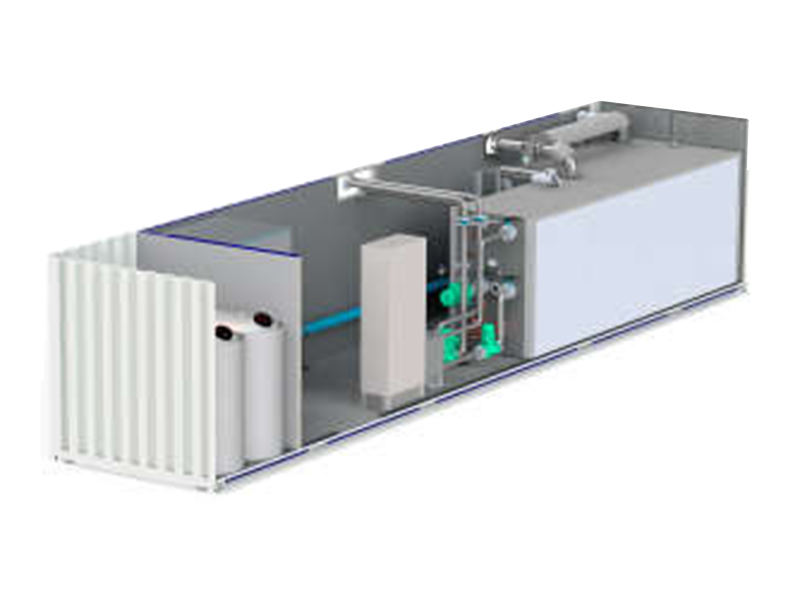

Binder silos and equipment

Individual equipment options:

- Heating and cooling systems

- Recycling systems

- Additive container

- Fiber dosing devices

- Wear protection linings

- Humidity and temperature measurement

Loading variants by means of wheel loader

or truck operation

Double belt loading

with wheel loader operation – above ground level

Overhead belt feeding

with wheel loader operation – above ground level

Drivable truck tasks

below floor level via double conveyor belt

VIDEO NISBAU [EINZIG] COMPACT 3.0

as a stationary version with a sunk aggregate store in Budapest