[mobile] 3.3

AS A FULLY MOBILE CONCRETE BATCHING PLANT [mobile]3.3 SETS NEW STANDARDS IN THE AREAS OF MOBILITY, PERFORMANCE AND ECONOMIC EFFICIENCY.

NISBAU [mobile]

MOBILITY-FLEXIBILITY-PERFORMANCE-ECONOMIC EFFICIENCY

OUR THIRD GENERATION OF FULLY MOBILE AND FOUNDATION-FREE SYSTEMS.

Be it seasonal capacity bottlenecks, long-term large construction sites, limited space or just a small time window – there are different scenarios for which there is only one solution, the use of a mobile mixing plant. Thanks to a foundation-free installation, the system can be set up, dismantled and relocated relatively inexpensively within a few days. The multitude of our configuration options enables us to offer you exactly the system that meets your needs. The options range from the optimal mixer size for you, the number of aggregate stores and binding agent silos to special automation. A horizontal and thus flat design allows installation in height-sensitive areas such as at airports.

Our systems reach your construction site completely wired, so that you can start your project immediately after a short set-up time.

MADE IN[GERMANY] – THAT’S A STATEMENT FOR US

POWERFUL SYSTEM TECHNOLOGY.

PACKED IN [MOBILITY] AND EFFICIENCY.

- MADE IN BOCKENHEIM IN THE GERMAN WIDE ROADS -OUR NEW STANDARDS AT A GLANCE:

Foundation-free installation

THROUGH SKID DESIGN

cooling and heating operation

INTEGRATED ACCESS RAMP

FOR WHEEL LOADER OPERATION

PLUG AND PLAY

assembly within one day

FEATURES

for the highest requirement profiles

THIS IS [EINZIG]

EQUIPMENT OPTIONS FOR OUR SYSTEMS:

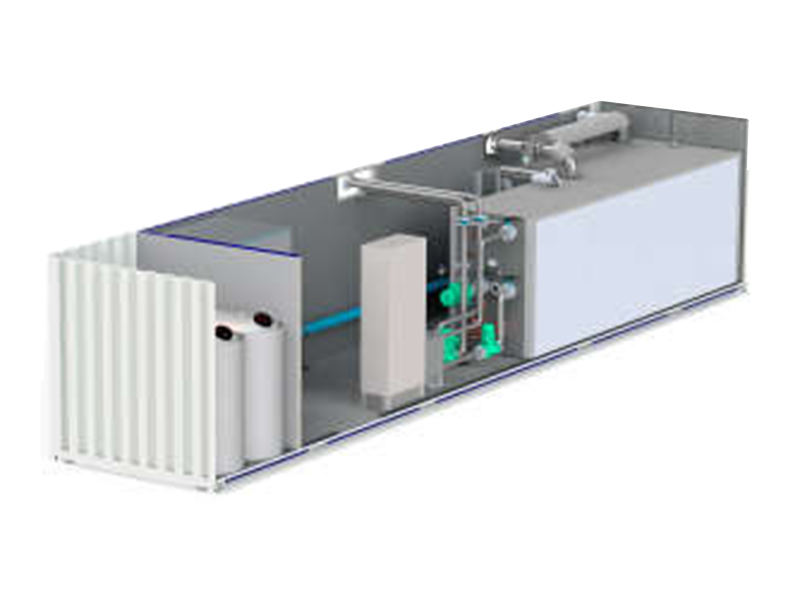

- HEATING AND COOLING SYSTEMS

- ADDITIONAL STORAGE

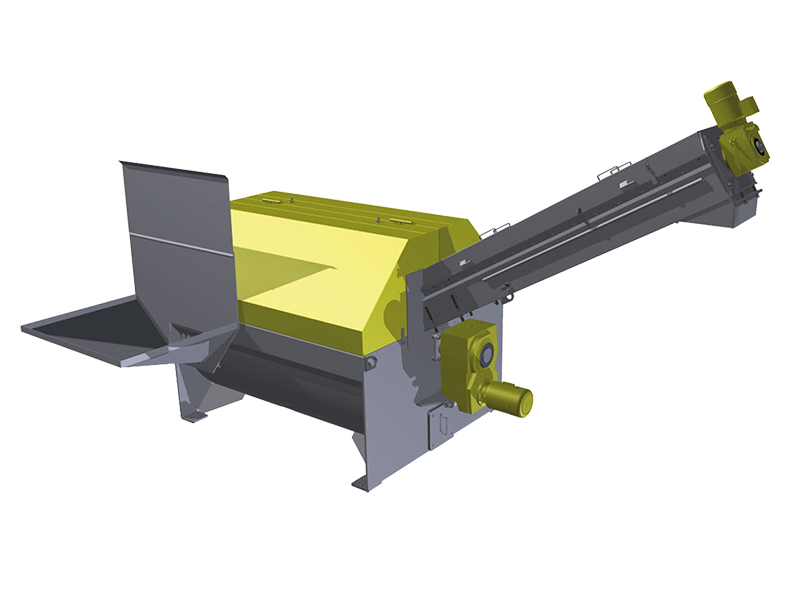

- RECYCLING SYSTEMS

- HIGH PRESSURE CLEANING SYSTEMS

- FIBER DOSING SYSTEMS

- INDIVIDUALLY ADAPTABLE CONTROL TECHNOLOGY WITH INTERFACE CONNECTION

- VARIOUS OPTIONS OF WEAR LINING – FROM PU TO HARDOX

Mixer sizes 2 – 3.3 m³

max 2 m³

BHS MIXING TECHNOLOGY

FOUNDATION-FREE INSTALLATION

HIGH PRESSURE CLEANING SYSTEM FOR THE MIXER

HUMIDITY AND TEMPERATURE MEASUREMENT

VIDEO SURVEILLANCE IN THE MIXER

Winter-proof housing

with optional heating lines

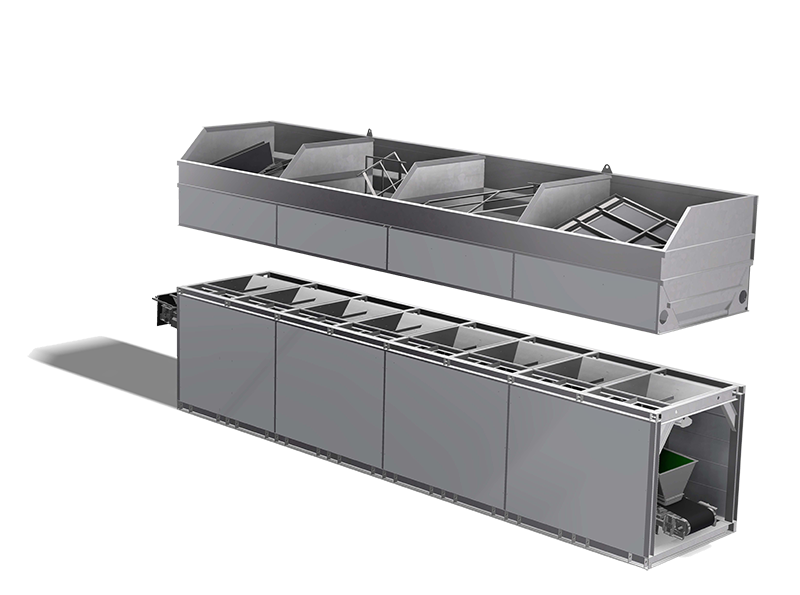

THREE TO SIX storage compartments

Adaptable:

Grate grids, moisture probes, covers, aggregate scales, wear lining in HARDOX and PU.

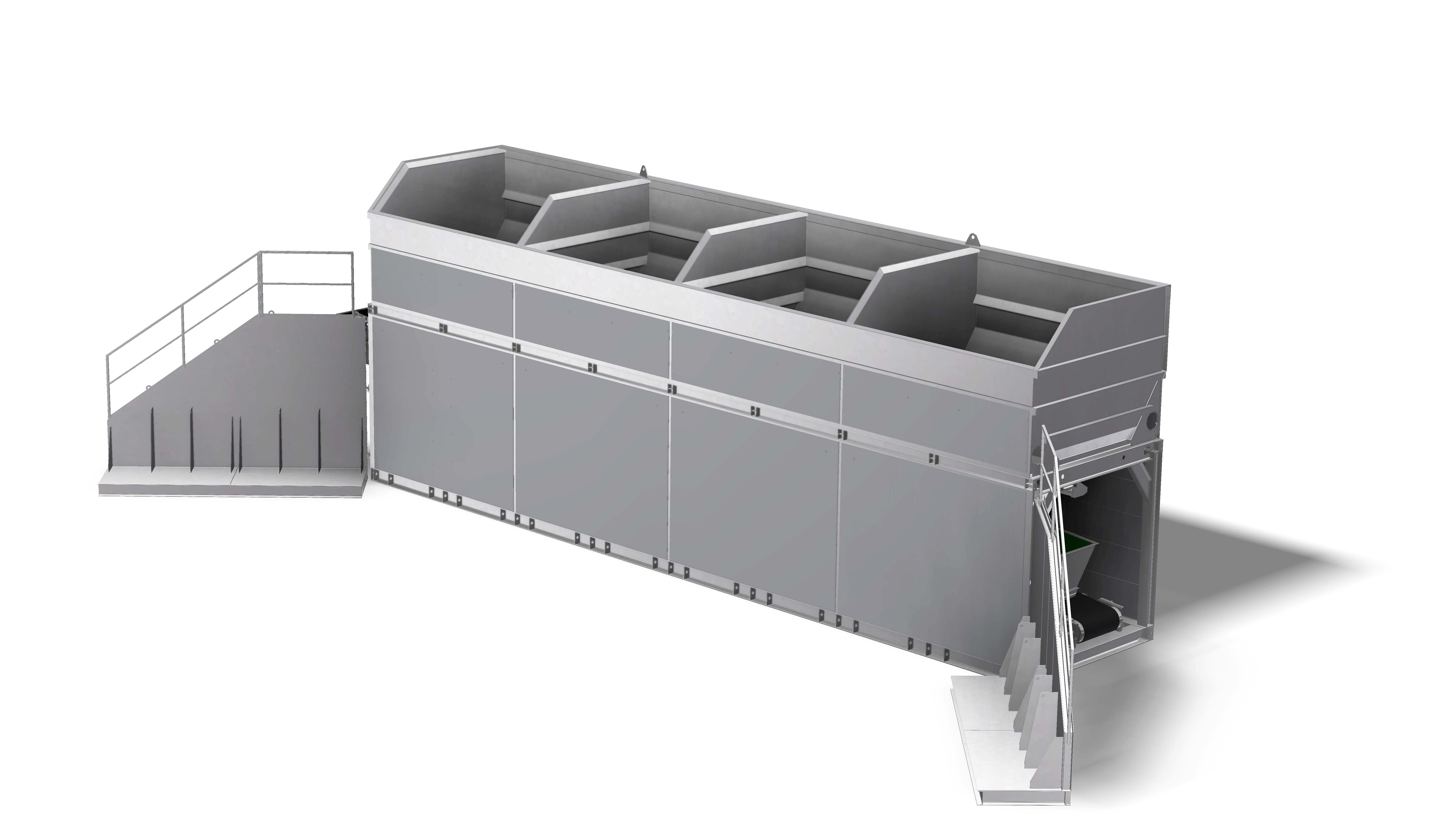

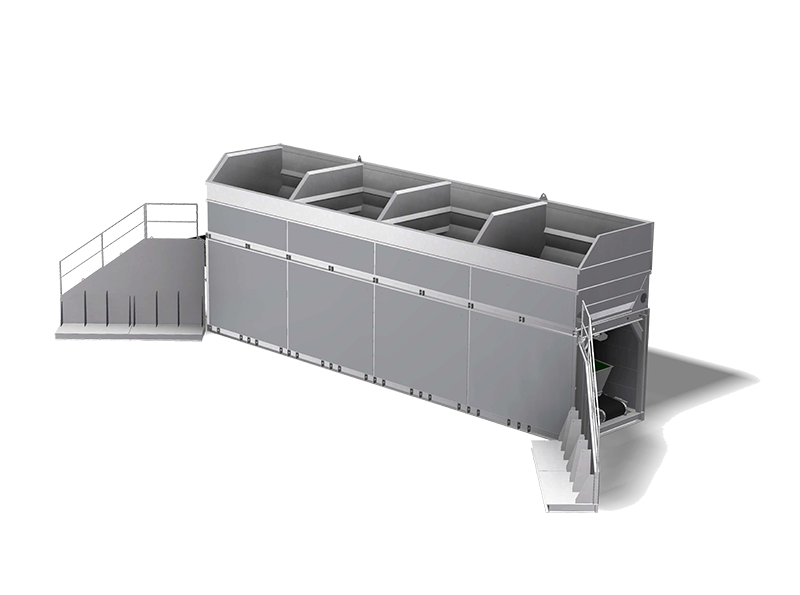

NISBAU [storage]

MODULAR AGGREGATE STORAGE WITH INTEGRATED steel ramp.

ROBUST – FULLY MOBILE – MODULAR – INDIVIDUALLY CONFIGURABLE

Foundation-free installation

Compartments

3-6

Volume

180 m³

Weighing belts

800 -1200.00 mm

Plug and Play

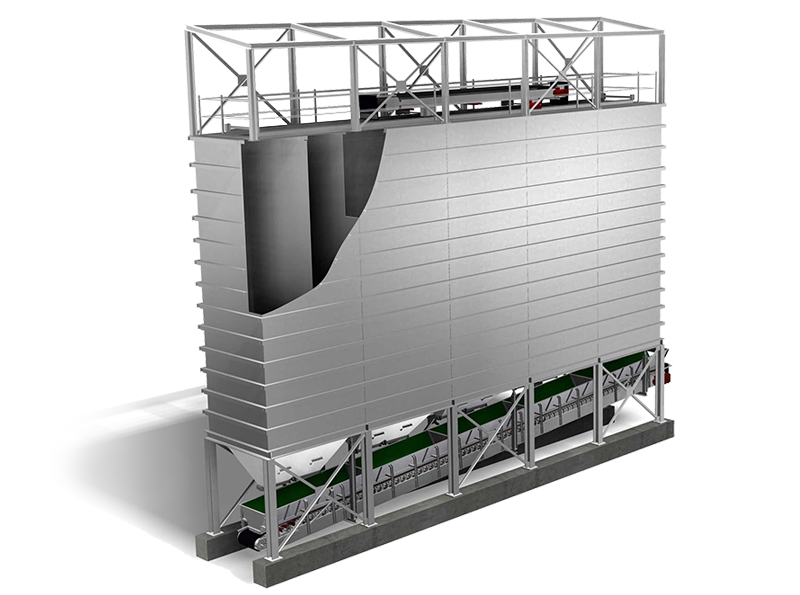

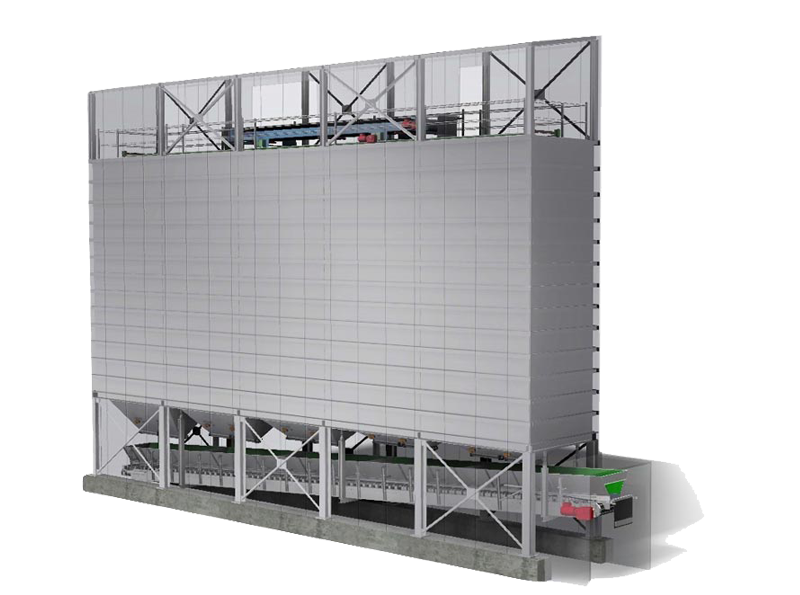

NISBAU [HIGH-STORAGE]

MODULAR HIGH SILOS WITH ADAPTABLE LOADING SYSTEMS

WHEN IT COMES TO FLEXIBLE CAPACITY.

max 132m³

[einzig]kind of compatibility.

we offer solutions for our customers.

Modular

Aggregate Storage

Aggregate Storage

Modular aggregate storage in horizontal design with integrated ramp construction.

Compartments: 3-6

Capacity: 25-30 m3 per compartment

High silo system in

modular construction

modular construction

High silo system in modular design. Modules are pre-wired with connectors at our factory. The insulation is integrated in the individual modules.

Sizes from 4-5 compartments and capacity from 132 m³ to 450 m³ .

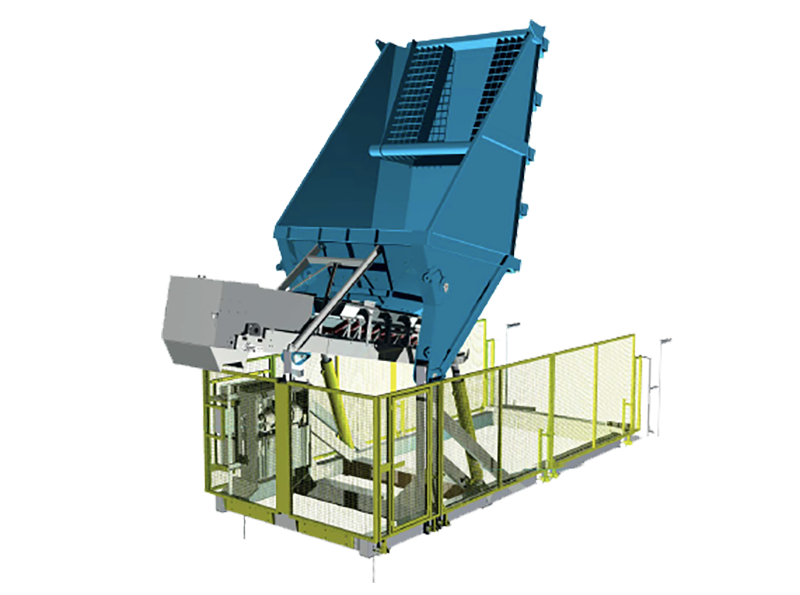

Loading systems

for wheel loader and truck operation

Feeding systems for every challenge.

Our portfolio includes the following systems:

- Feeding systems

- Double conveyor belt

- Skip bucket elevators

- Overhead conveyor belt

- Conveyor systems

Binder silos in horizontal

or vertical configuration

or vertical configuration

Binder silos in horizontal and vertical design as well as mobile foundations.

Indivual

optional equipment

Individual equipment options:

- Heating and cooling systems

- Recycling systems

- Additive container

- Fiber dosing devices

- Wear protection linings

- Humidity and temperature measurement